CO2 transcritical system selected for the Beijing Winter Olympics 2022

The Beijing 2022 Organising Committee recently announced its decision to use CO2 refrigeration systems in most of its venues for the 2022 Winter Olympics. This landmark decision aligns with several factors that were of importance to the committee, including achieving the best ice quality, system reliability, securing a sustainable, environmentally friendly solution and maximizing energy efficiency.

Sustainability Objectives

This move came after the Beijing Organising Committee joined the UN Sports for Climate Action Framework, led by the International Olympic Committee. They have two overarching goals clearly outlined: to set a clear trajectory for sports communities to combat climate change, and to use sports as a unifying tool among citizens worldwide for climate action.

In accordance, the move to CO2 could reduce carbon emissions by over 26 million kilograms annually.

A decision of such magnitude requires significant research, and delegates from Beijing conducted on-site Canadian visits to facilities in Vancouver and Calgary, as well as to other sites in North America and Europe. Operational data was provided for each of the systems and the use of NH3, Freon and CO2 was analyzed and compared.

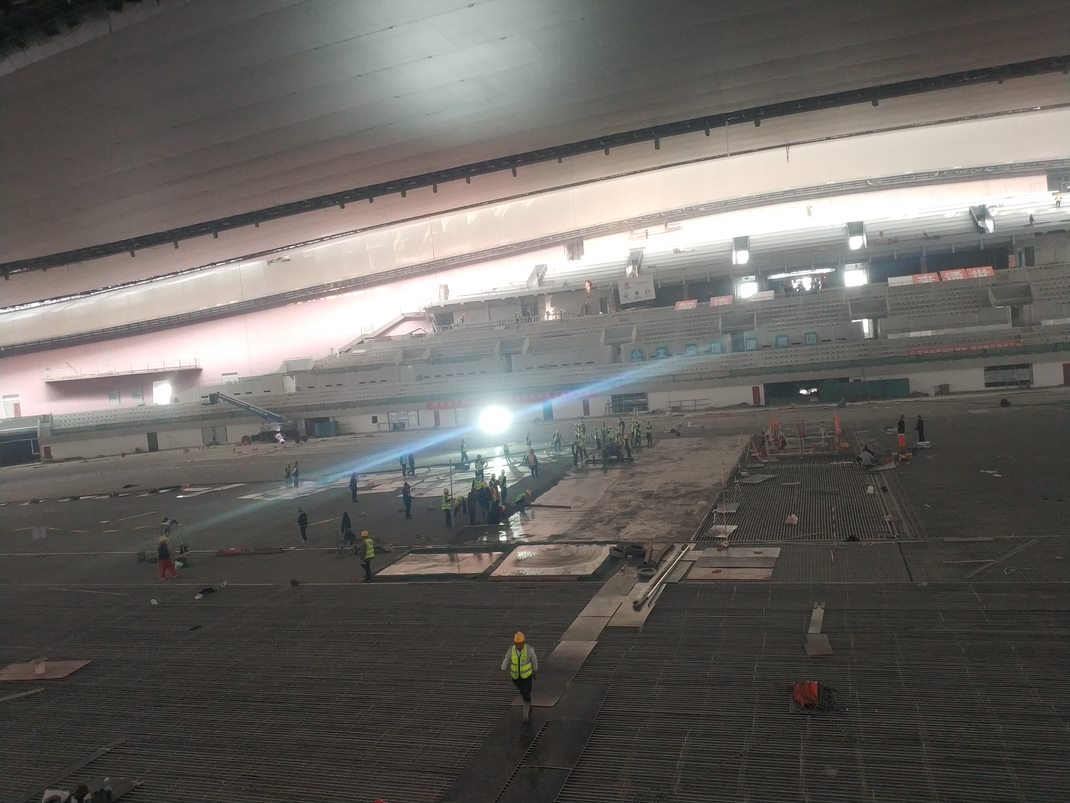

Eventually, a CO2 transcritical system was selected for the Beijing speed skating oval. CO2 was chosen based on its efficiency, environmental impact, life cycle, and ice quality. This marks the first time in history that a transcritical CO2 system will be used to make ice at the winter Olympics.

This decision could help address the issue of climate change in both China and globally, as noted by Juan Antonio Samaranch, Chair of the IOC Coordination Commission for these Games. “We are pleased to see that the IOC’s close collaboration with Beijing 2022 has resulted in such an important outcome.”

The Refrigeration System

The CO2 transcritical system recommended by CIMCO is approximately 1000 TR, based on 5°F Suction and 100°F Condensing. The oval and support facilities will seat 12,000 spectators. The Transcritical CO2 system released for tender included:

- 6 skids, each with 6 compressors providing approx. 190 TR at -18°C SST and 38°C SCT

- 6 Adiabatic gas coolers, 1 per skid

- 4 CO2 Recirculator Vessel Packages each complete with 2 CO2 pumps each

- Vessels connected to common suction and common liquid drains

- Floor design consisting of 10 refrigerated floor zones including 2 track zones and 2 arenas with dedicated pumping systems, the other 6 zones connected into 2 pumping systems but with individual zone valves and temperature control

- Floor network constructed of stainless 20 mm (3/4 in) pipe and stainless headers sized to the flow rate

As part of a four party consortium, CIMCO Refrigeration is providing the consulting services, which includes reviewing the system design, making recommendations or modifications to the design criteria, and developing and overseeing the commissioning and quality control parameters for the project.

Related Posts

Decarbonization Trends Shaping Industries

Woolwich Memorial Centre Achieves Energy Excellence with CIMCO’s Eco Chill

10 Simple Fixes to Boost Efficiency in Aging Refrigeration Plants

|

|

.png?sfvrsn=a8a2c222_0)